For Petrochemical Small Rotary Drilling Rig by

Product details of the small rotary drilling rig

Quick Detail

The materials of small rotary drilling rig is safe, do no harm to human health. The product is well received by customers for its high performance and durability. small rotary drilling rig can meet the different needs of customers. WORLD MACHINERY SOLUTIONS CO.,LIMITED provide OEM and ODM services to worldwide partners.

Product Information

In order to strengthen your understanding of small rotary drilling rig, will show you the specific details of small rotary drilling rig in the following section.

|

Large diameter bored pile |

||

|

Max pile diameter |

mm |

2500 |

|

Max pile depth |

m |

77 |

|

Max casing diameter |

mm |

2000 |

|

Undercarriage |

||

|

Overall length |

mm |

5550 |

|

Track shoe width |

mm |

900 |

|

Overall width (extended side frames) |

mm |

4480 |

|

Overall width (retracted side frames) |

mm |

2980 |

|

Ground pressure |

MPa |

0.095 |

|

Diesel engine |

||

|

Model |

type |

DEUTZ TCD 2015 V06 |

|

Power |

KW(HP) |

3601482 |

|

Hydraulic pumps |

||

|

Main pumps |

It/min |

2x304 |

|

Auxiliary pumps |

It/min |

93 65 53 38 23 |

|

Max working pressure |

MPa |

30 |

|

Main winch |

||

|

1st layer nominal line pull |

KN |

240 |

|

1st layer nominal rope speed |

m/min |

80 |

|

Rope diameter |

mm |

30 |

|

Auxiliary winch |

||

|

1st layer nominal line pull |

KN |

140 |

|

1st layer nominal rope speed |

m/min |

90 |

|

Rope diameter |

mm |

26 |

|

Rotary (3 shifting gear box high speed) |

||

|

Maximum nominal torque |

kNm |

271/146/29 |

|

Max spin off speed |

rpm |

|

|

Maximum drilling speed |

rpm |

30/55/115 |

|

Rotary (without shifting gear box) |

||

|

Maximum nominal torque |

kNm |

266 |

|

Max spin off speed |

rpm |

125 |

|

Maximum drilling speed |

rpm |

30 |

|

Crowd cylinder |

||

|

Crowd force (pull down/pull up) |

KN |

201/264 |

|

Pull down stroke |

mm |

6500 |

|

Winch crowd system |

||

|

Crowd force (pull down/pull up) |

KN |

200/320 |

|

Pull down stroke |

mn |

15800 |

Application

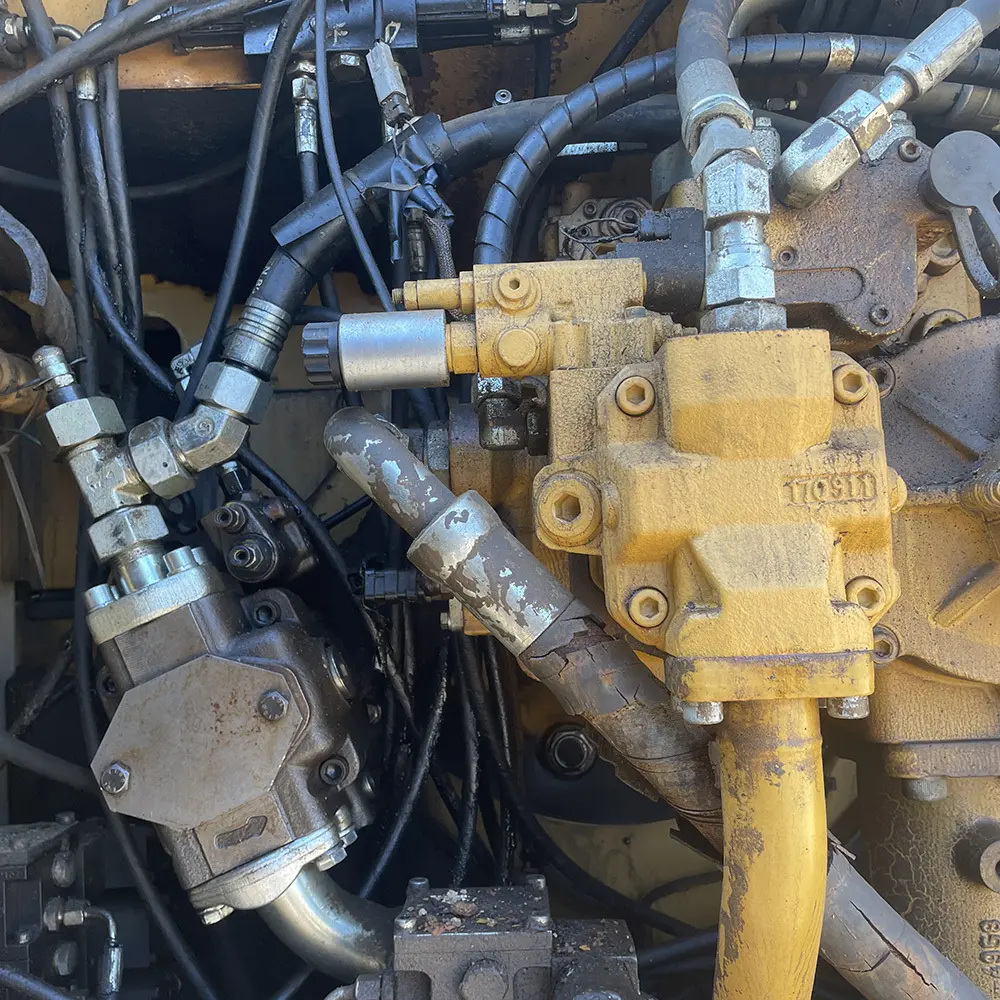

The hydraulic drilling rig SR-70 is mounted on SOILMEC base carrier and has been specially designed for suiting the following applications:

● Cased bore piles with casing driven directly through rotary head or optionally by casing oscillator powered by the base carrier itself;

● Very deep bored piles stabilized by drilling fluid or dry hole;

● CFA piles by means of very long auger string;

● CSP/CAP piles with double rotary;

● Displacement piles;

● Soil-mixing;

● Reverse circulation;

● It can be converted to work with an hydraulic grab for diaphragm walls.

The SR-70 is equipped with the DRILLING MATE SYSTEM (DMS) on 12” touch screen for monitoring and control of the operating parameters

Features

1 - Undercarriage with expandable tracks from 2980 to 4480 mm by means of hydraulic cylinders

2 - Turret c/w DEUTZ TCD 2015 V06 diesel engine and sound proofed canopy, mounted on a 360° slew ring

3 - Winch assembly fixed by 2 pins each winch, for easy removal

4 - New design parallelogram system, especially shaped to fit crowd winch in transport condition. Allowing working radius adjustment always maintaining the mast in vertical position. C/w electronic device for automatic stop

5 - Self-erecting mast composed by an intermediate element 13,5 m long and a top element with 1,5 m extension. The max torque can be applied all over the mast length. Multipurpose design for cylinder and winch crowd system

6 - Sheave cathead with lateral mounted service rope pulley

7 - Crowd system by means of 6,5 m stroke hydraulic cylinder or 16,5 m stroke winch (2nd line pull)

8 - Rotary head with variable displacement motors and one high spin off speed. Two speed gear available (optional)

9 - Telescopic kelly bar with guide to mast, available with friction or mechanical locking type

10 -Self mounting type counterweight by means of hydraulic cylinders. It can be easily and quickly removed for transport purpose

11 -New design cabin with more ergonomic operato’s place

Company Introduction

WORLD MACHINERY SOLUTIONS CO.,LIMITED is thousands of people's choice when they are in need of high quality small rotary drilling rig. WORLD MACHINERY SOLUTIONS CO.,LIMITED has employed a group of technical talents with academic degrees. Customers can be sure that their products — whatever stage of the process — are under our strict production control and in the hands of experts at all times. Inquire online!

If you have any questions, feel free to consult us.

Contact person: Miya Miao

Mobile: +86 15026518796

Email: Jasminemachinery@aliyun.com