For Petrochemical Machines Used in Oil Rigs by

Company Advantages

· machines used in oil rigs is designed by professional designers with rich industry experience.

· The product is reliable in quality because it is produced and tested according to the requirements of widely recognized quality standards.

· This product shows great market prospects and limitless potential.

Company Features

· As a developer and producer of machines used in oil rigs of a high standard, WORLD MACHINERY SOLUTIONS CO.,LIMITED lives up to the name of a strong competitor in the market.

· Our company has won many awards. It gives us great pleasure when we win awards because it means other people think we’re doing a really good job too.

· Our sustainability work is integrated into our business culture and values. In our operation, we will work to ensure that production wastes are lawfully handled and resources are fully utilized.

Application of the Product

machines used in oil rigs can be applied to different industries, fields and scenes.

While providing excellent products, is dedicated to providing personalized solutions for customers according to their needs and actual situations.

Application

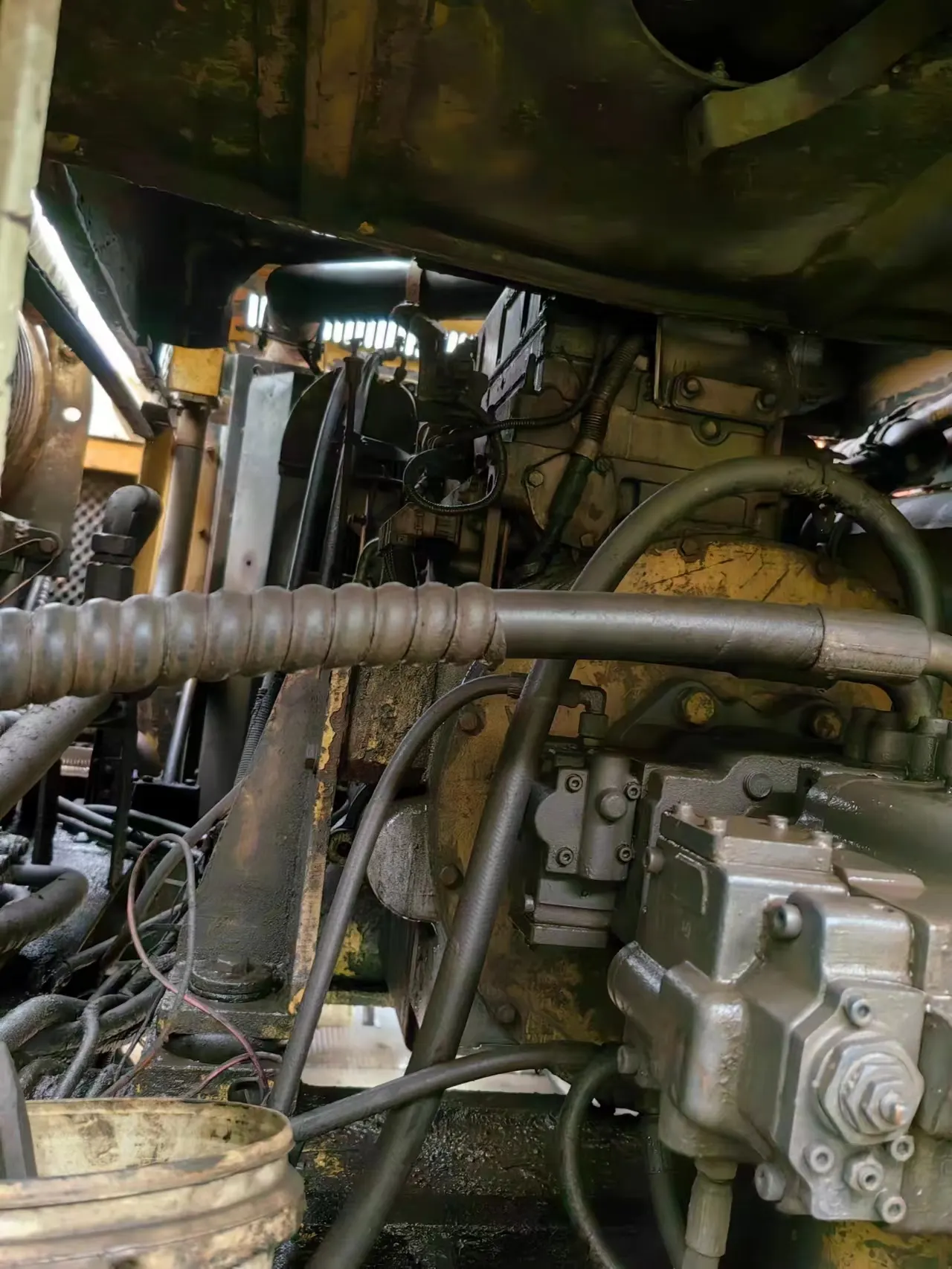

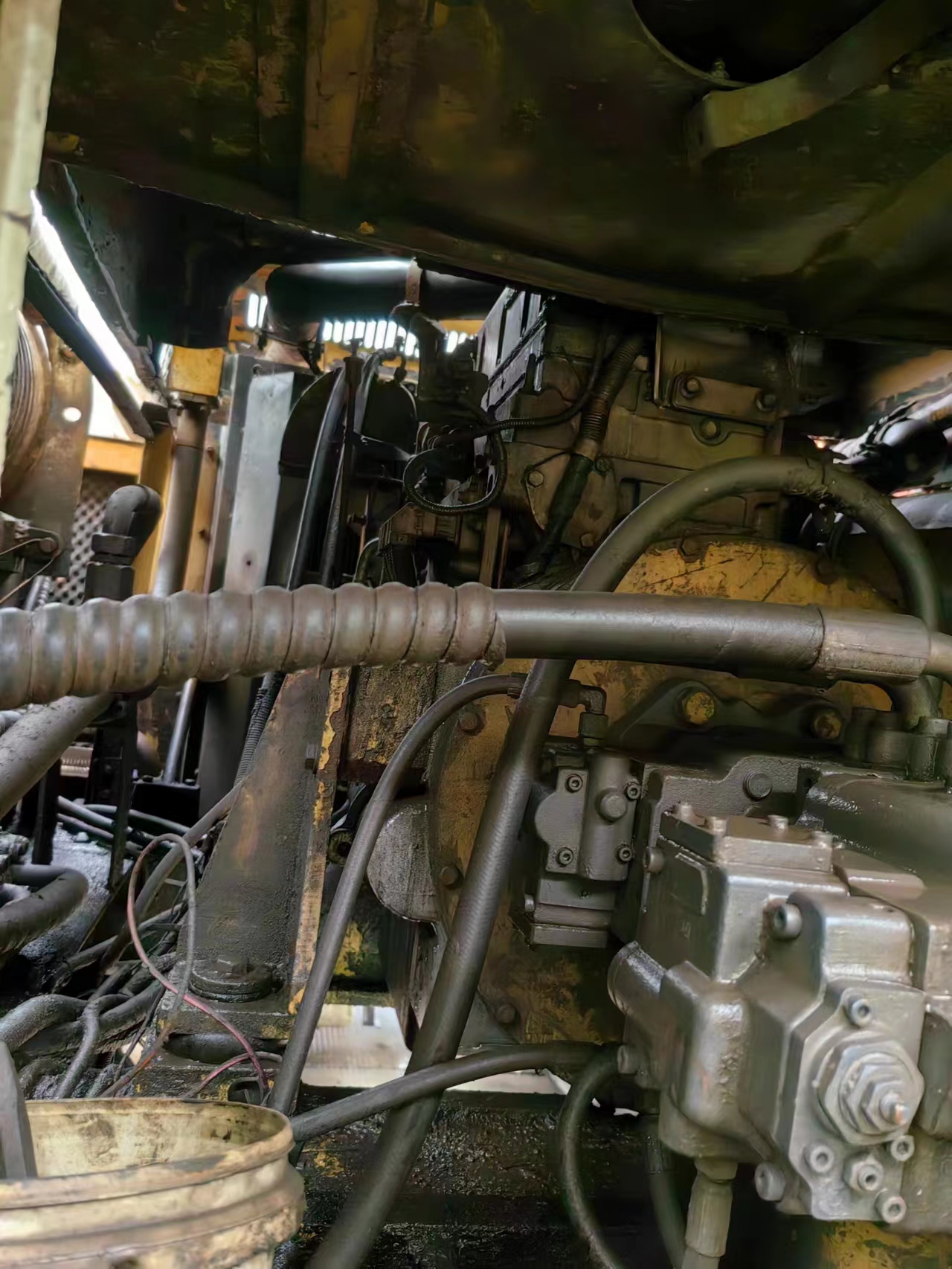

The YTR230 tracked rotor digging rig is one of Yutong Heavy Industry Rotor Diamond Serial Innovation Products. It is a large -scale rotary drilling rig developed by a large number of market demand surveys. It has a strong construction capacity and a wide range of use. It can be compatible with different construction areas to improve the adaptive ability of the whole machine. YTR230 rotor digging rigs are set up to impact rocks, high -speed soil, spiral rigs, multi -gear control, etc. Multi -functional new type of rock rotor digging rig.

Features

1.Imported dedicated chassis, Scania Edar engine, national three -stage emission standards, strong power, energy saving and environmental protectionRotate the power of the power brake, which is more suitable for excavation of high load and frequent impact.Walking mechanisms with large exhibition width, ultra -low center of gravity, and super -hard materials are equipped with special tightening mechanisms and reasonable processing techniques to ensure strong, reliable, and stable walking mechanism site adaptability.

2.Reliable performance,Each rig will go through 16 hours of sand playing tests before leaving the factory to test various technical parameters according to the test outline.

3.High -efficiency main roll,Under the improvement of the main volume, the hydraulic hydraulic flow technology can be increased, which can double the increase of the drilling tools, greatly shorten the time of the drilling machineless operation, and increase the efficiency of single -cycle operations by 3%; The slag amount.

4.Automatically rotating power head,The automatic rotation function of the power head can reduce the strength of the machine's hand -operated operation and keep the power head speed in the most efficient state.

5.Dynamic head consumption,Optimize the installation structure inside the power head box, increase the scraper, and increase the oil seal life by 30%.The inner keycase bar adopts a wear -resistant steel plate and embolism, and the life span is improved and the maintenance costs are lower.

Contact person: Miya Miao

Mobile: +86 15026518796

Email: Jasminemachinery@aliyun.com